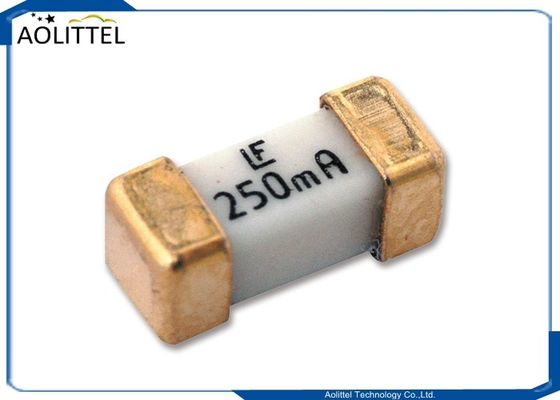

UL CUL 10.1mmx 3.1mm 4012 Fast-Acting Chip Fuse CQ40LF 500mA-40A 600VAC 350VDC With High Inrush High Breaking Capacity

Application

• Storage system power

• Cooling fan system for PC server

• Voltage regulator module

• Base station power supply

• Voltage regulator module for PC server

• High end servers / Blade computing

• Battery Management System

Main Features

• Surface mount high current fuse

• Available in ratings of 20 to 60 Amperes

• Higher voltage rating up to 100VDC

• 10.25×3.20 (mm) square shape surface mount

• Operating temperature range from -55°C to 125°C

• Enhanced thermal cycling endurance

• RoHS compliant and Halogen Free

Materials & Dimension

Construction Body Material: Ceramic

Termination Material: Silver(Ag),Nickel(Ni),Tin(Sn)

Fuse Element: Silver(Ag)

Recommended Land Pattern--Reflow Solder

Unit:mm

| |

L2 |

L1 |

W |

| 1-30A |

6.1 |

3.25 |

3.43 |

Part Numbering

Part number system

CQ40LF 001

CQ40LF -- Series

001 -- AMP Code (Refer to below table )

| PN |

Ampere

Rating

[ In ] |

Voltage

Rating

( V ) |

Nominal

Resistance

Cold Ohms |

Nominal

Melting I t

A Sec |

| CQ40LF.500 |

500mA |

600VAC

350VDC

|

0.3510 |

2.300 |

| CQ40LF1.25 |

1.25A |

0.0750 |

17.000 |

| CQ40LF002 |

2A |

0.0560 |

37.000 |

| CQ40LF020 |

20A |

0.0050 |

30.000 |

| CQ40LF030 |

30A |

0.0025 |

96.000 |

| CQ40LF040 |

40A |

0.0019 |

600.000 |

Electrical Characteristic

| Rated current |

1 In |

2 In |

| Min. |

Max. |

| 0.5-40A |

4 hour |

5 sec |

Environmental Temperature at 25°C

Interrupting Rating

0.5A~40A :

150 amperes at 350V DC

150 amperes at 600V AC

Soldering Method

*Reflow Soldering : 260°C, 30Sec. max.

*Wave Soldering : 260°C, 10Sec. max.

*Hand Soldering : 350°C, 3Sec. max.

Tape and Reel Specification

Tape & Reel Quantity: 1000PCS/Reel

| Item |

W |

P |

E |

F |

P1 |

D |

D1 |

| Criterion |

16.00 |

8.00 |

1.75 |

7.50 |

2.00 |

1.50 |

1.50 |

| Tolerance |

±0.10 |

±0.10 |

±0.10 |

±0.05 |

±0.05 |

±0.10 |

±0.10 |

| Item |

P0 |

10P0 |

A0 |

B0 |

KO |

t |

| Criterion |

4.00 |

4.00 |

3.52 |

10.58 |

1.50 |

0.30 |

| Tolerence |

±0.10 |

0.20 |

±0.10 |

±0.10 |

±0.10 |

±0.05 |

Environmental Specification

| Operating Temperature |

-55°C to +125°C |

| Vibration |

MIL-STD-202G, Method 201(10-55 Hz, 0.06 inch, total excursion) |

| Salt Spray |

MIL-STD-202G, Method 101, Test Condition B (48Hrs) |

| Insulation Resistance |

MIL-STD-202G, Method 302, Test Condition A |

| Resistance to Solder Heat |

MIL-STD-202G, Method 210, Test Condition B (10sec, at 260°C) |

| Thermal Shock |

MIL-STD-202G, Method 107, Test Condition B (-65°C to +125°C) |

Storage

The ambient temperature shall be kept between 5℃~30℃.

The relative humidity recommended for storage is between 25%~ 60%.

Sealed plastic bags with desiccant shall be used to reduce the oxidation of the termination and shall only be opened prior to use.

The products shall not be stored in areas where harmful gases containing sulfur or chlorine are present.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!