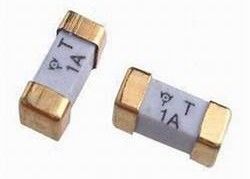

High Voltage Explosion Proof 10.1x3.1mm 4012 Time Delay Surface Mount Fuse 1A 600VAC 350VDC

AOLITTEL NANO² SMD fuse is ideal for use in Datacom and telecom equipment

NANO² fuse is a fast-acting, very high current fuse designed for high operating current applications. It offers enhanced thermal cycling endurance (up to 500 cycles). Its low temperature rise and excellent temperature stability characteristics make it ideal for use in Datacom and telecom equipment like high-end servers, base stations, power supplies, and blade computing applications. offers high-amp circuit protection, ultra-high interrupting ratings (up to 500 A at 72 VDC), and a compact (10.1 mm x 3.12 mm x 3.12 mm) surface-mount form factor to save board space.

Features & Benefits

High current rating (15 – 30 A) with higher voltage up to 100 VDC

Enhanced thermal cycling endurance

High melting i2t

Surface-mount fuse in a small footprint

Operating temperature range from -55°C to 125°C

Enables blade servers operating at higher power

Provides higher reliability in harsh thermal cycling conditions

Prevents nuisance tripping caused by transient surge during blade server hot swapping

Allows for greater flexibility in fuse placement on slim blade server boards

Ensures robust performance and reliable protection in ultra-high ambient temperature working environments

Materials & Dimension

Construction Body Material: Ceramic

Termination Material: Silver(Ag),Nickel(Ni),Tin(Sn)

Fuse Element: Silver(Ag)

Recommended Land Pattern--Reflow Solder

Unit:mm

| |

L2 |

L1 |

W |

| 1-40A |

6.1 |

3.25 |

3.43 |

Part Numbering

Part number system

CQ40LT 001

CQ40LT -- Series

001 -- AMP Code (Refer to below table )

| PN |

Ampere

Rating

[ In ] |

Voltage

Rating

( V ) |

Nominal

Resistance

Cold Ohms |

Nominal

Melting I t

A Sec |

| CQ40LT001 |

1A |

600VAC

350VDC

|

0.8500 |

0.5800 |

| CQ40LT002 |

2A |

0.4000 |

1.1100 |

| CQ40LT020 |

20A |

0.0060 |

32.630 |

| CQ40LT030 |

30A |

0.0030 |

136.89 |

| CQ40LT040 |

40A |

0.0014 |

547.10 |

Electrical Characteristic

| Rated current |

1 In |

2 In |

3 In |

8 In |

| Min. |

Min. |

Max. |

Max. |

Max. |

| 1-40A |

4 hour |

1sec |

60 sec |

3 sec |

0.1 sec |

Environmental Temperature at 25°C

Application

High end servers / Blade computing

Base station power supply

Voltage regulator module

Cooling fan system for PC Server

Advance Telecommunication Computing Architecture (ATCA) applications for cloud computing

Battery Management System (Industrial Tools)

Interrupting Rating

1A~30A :

150 amperes at 350V DC

150 amperes at 600V AC

600 amperes at 60V DC

40A: 600 amperes at 60V DC

Soldering Method

*Reflow Soldering : 260°C, 30Sec. max.

*Wave Soldering : 260°C, 10Sec. max.

*Hand Soldering : 350°C, 3Sec. max.

Tape and Reel Specification

Tape & Reel Quantity: 1000PCS/Reel

Product Characteristics

Materials

Body : Ceramic

Ceramic Cap : Silver Plated Brass

Insulation Resistance (after Opening) MIL-STD-202, Method 302, Test Condition A (10,000 ohms, Minimum)

Solderability MIL-STD-202, Method 208

Resistance to Soldering Heat MIL-STD-202, Method 210, Test Condition B (10 sec at 260°C) PCB Recommendation for Thermal Management Min. copper layer thickness = 100µm

Minimum copper trace width = 10mm

Alternate methods of thermal management may be used. In such cases, under normal operations, the maximum temperature of the fuse body should not exceed 80°C in a 25°C environment.

Operating Temperature –55ºC to 125ºC with proper derating

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!