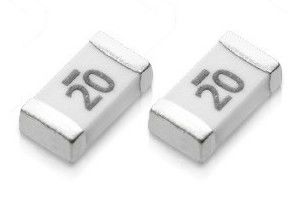

CQ12LI Type 3216 High Current Surface Mount Device Time-Lag Ceramic Fuse 3.1×1.6mm 24V 63V 10A-30A

Approval Recognized Component for Canada and U.S. 10A~30A

Interrupting Rating

10A~25A: 100 amperes at 63V AC/DC

250 amperes at 24V AC/DC

35A: 100 amperes at 24V AC/DC

Application

Voltage Regulator Module (VRM) Equipment,

DC-DC Converter,

Battery Pack

Electrical Characteristic

| Rated current |

1 In |

3.5 In |

| MIN |

MAX |

| 10A~30A |

4hr |

5 SEC |

Dimension

Part numbering

| P/N |

Ampere

Rating

[ In ] |

Voltage

Rating

( V ) |

Nominal

Resistance

Cold Ohms |

Nominal

Melting I²t

A² Sec |

| CQ12LI 010 |

10A |

24V |

0.0054 |

14.0 |

| CQ12LI 012 |

12A |

0.0040 |

19.0 |

| CQ12LI 015 |

15A |

0.0033 |

33.0 |

| CQ12LI 020 |

20A |

0.0020 |

56.0 |

| CQ12LI 025 |

25A |

0.0017 |

182 |

| CQ12LI 030 |

30A |

0.0013 |

260 |

1. Measured at ≤ 10% of rated current and 25ºC.

2. Melting I²t at 1000% of current rating.

3. Certified (cRUus) and Customized up to 125V

4. Application testing is strongly recommended.

Features

a. High voltage and high current rating

b. High inrush and high breaking capacity

c. Fast arcing extinguished

d. Lead free & Halogen free material

e. Good explosion proof

f. Precise fusing time and cut-off completed

g. Suitable for rated current of 1A ~20A

Environmental Specification

Operating Temperature -55°C to +125°C

Vibration MIL-STD-202G, Method 201(10-55 Hz, 0.06 inch, total excursion)

Salt Spray MIL-STD-202G, Method 101, Test Condition B (48Hrs)

Insulation Resistance MIL-STD-202G, Method 302, Test Condition A

Resistance to Solder Heat MIL-STD-202G, Method 210, Test Condition B (10sec, at 260°C)

Thermal Shock MIL-STD-202G, Method 107, Test Condition B (-65°C to +125°C)

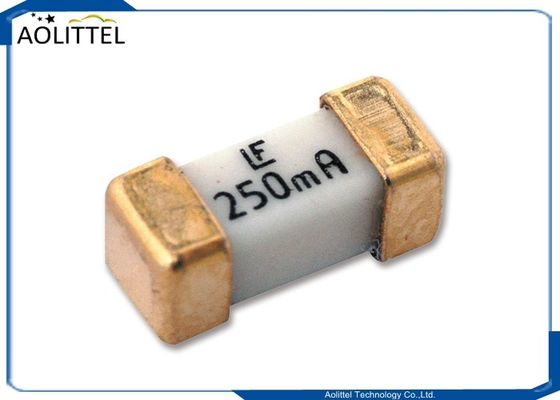

Physical Specification

Material Construction

Body Material: Ceramic

Termination Material: Silver(Ag),Nickel(Ni),Tin(Sn)

Fuse Element: Silver(Ag)

Packaging

1. Tape & Reel : 8mm tape

2. Packaging Specification : EIA Standard 481-D

3.Quantity : 4,000 pcs per reel.

FUSE SELECTION GUIDE

The fuse must carry the normal load current of the circuit

without nuisance openings.However,when an over current

occurs the fuse must interrupt the over current,limit the energy

let-through,and withstand the voltage across the fuse during

acting.To properly select a fuse the followings must be

considered:

(1)Normal operating current(The current rating of a fuse is

typically derated 25% for operation at 25% to avoid nuisance

blowing.For example,a fuse with 10A current rating is not

usually recommended for operation at more than 7.5A in a

25% derating.)

(2)Overload current and melting time of the fuse.

(3)Application volage(AC or DC voltage).

(4)Inrush currents,surge currents,pulses,start-up currents

characteristics.

(5)Ambient temperature.

(6)Applicable standards agency required,such as UL,CSA,

TUV,VDE,PSE and IEC....

Considerations: Reduce installed cost,ease of removal,

(7)mounting type/form factor,etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!