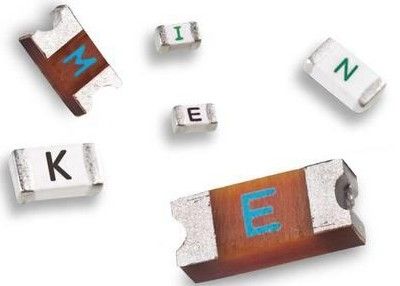

3216 SinglFuse Automated Assembly Fast Acting Surface Mount Fuse 12D1200 2A 63V For Overcurrent Protection

Features

Fast acting precision thin film chip fuse for overcurrent protection

3216 (EIA 1206) miniature footprint

Surface mount packaging for automated assembly

UL listed (UL 248-14)

RoHS compliant* and halogen free

Part Numbering

| Catalog |

Ampere |

Voltage |

Marking |

Melting Integral |

| No. |

Rating |

Rating |

(A2.S) |

| 12D0250C |

250mA |

63V |

.25 |

0.0035 |

| 12D0375C |

375mA |

63V |

● |

0.0011 |

| 12D0500C |

500mA |

63V |

0.5 |

0.0020 |

| 12D0750C |

750mA |

63V |

.75 |

0.0053 |

| 12D1100C |

1A |

63V |

1 |

0.0065 |

| 12D1125C |

1.25A |

63V |

▲ |

0.020 |

| 12D1150C |

1.5A |

63V |

1.5 |

0.025 |

| 12D1200C |

2A |

63V |

2 |

0.091 |

| 12D1250C |

2.5A |

63V |

2.5 |

0.150 |

| 12D1300C |

3A |

63V |

3 |

0.329 |

| 12D1400D |

4A |

32V |

4 |

0.225 |

| 12D1500D |

5A |

32V |

5 |

0.564 |

| 12D1700D |

7A |

32V |

7 |

3.197 |

| 12D2100E |

10A |

24V |

10 |

2.162 |

| 12D2120E |

12A |

24V |

12 |

7.100 |

| 12D2150E |

15A |

24V |

15 |

23.893 |

| 12D2200E |

20A |

24V |

20 |

47.172 |

Time-current features

| Ampere Rating |

Ampere Rating |

Opening Time |

| 250mA~20A |

100% |

4 hours Min |

| 250mA~3A |

250% |

5 s Max |

| 4A~20A |

350% |

5 s Max |

Reliability

Testing Parameter Requirement Test Method

Carrying Capacity..................................... No fusing................................................Rated current, 4 hours Fusing Time..............................................Within 5 seconds.................................200 % of its rated current Interrupting Ability..................................... No mechanical damages ....................After the fuse is interrupted, rated voltage applied for 30 seconds again

Bending Test............................................. No mechanical damages ..................Distance between holding points: 90 mm, Bending: 3 mm,1time, 30 seconds

Resistance to Solder Heat........................ ±20 %...................................260 °C ±5 °C,10 seconds ±1 second

Solderability.............................................. 95 % coverage minimum ...........................235 °C ±5 °C, 2 ±0.5 second 245 °C ±5 °C, 2 ±0.5 second (lead free)

Temperature Rise ..................................... <75 °C........................................100 % of its rated current, measure of surface temperature

Resistance to Dry Heat............................. ±20 %..................................................105 °C ±5 °C,1000 hours

Resistance to Solvent............................... No evident damage on protective ..........23 °C ±5 °C of isopropyl alcohol, 90 seconds coating and marking

Residual Resistance................................. 10k ohms or more..................Measure DC resistance after fusing

Thermal Shock ......................................... DR < 10 %................-20 °C / +25 °C /+125 °C /+25 °C, 10 cycles

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!