Why use an RTD instead of a thermocouple or thermistor sensor?

Each type of temperature sensor has a particular set of conditions for which it is best suited. RTDs offer several advantages:

• A wide temperature range (approximately -200 to 850°C)

• Good accuracy (better than thermocouples)

• Good interchangeability

• Long-term stability

With a temperature range up to 850°C, RTDs can be used in all but the highest-temperature industrial processes. When made using metals such as platinum, they are very stable and are not affected by corrosion or oxidation. Other materials such as nickel, copper, and nickel-iron alloy have also been used for RTDs. However, these materials are not commonly used since they have lower temperature capabilities and are not as stable or repeatable as platinum.

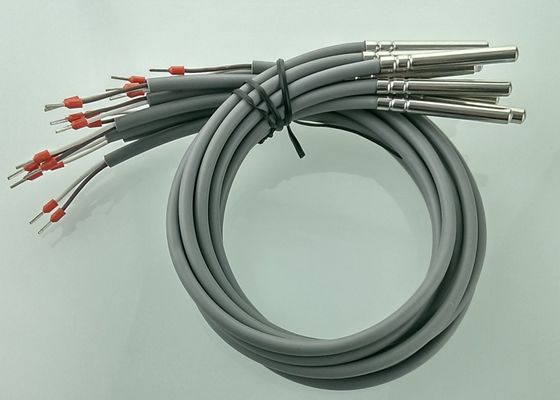

Measuring the temperature of a liquid with an RTD

Probe-type sensor styles are normally used for measuring liquids. They can be as simple as our general purpose RTD Probes PR-10 and PR-11 constructions, or as involved as our PR-12, 14, 18, or 19&sh;with connection heads and transmitters. A popular choice is the quick-disconnect sensor. This can be used as is, with compression fittings for flexible installation, or with our PRS plastic handle for a handheld probe. When measuring the temperature of harsh environments such as plating baths or highly pressurized systems, sensors can be coated with a material like PFA, or they can be housed in a thermowell to protect the sensor from extreme conditions.

Air and Gas Temperature Measurement with RTD Sensors

Air and gas stream measurements are a challenge because the rate of transfer of temperature from the fluid to the sensor is slower than for liquids. Therefore, sensors specifically designed for use in air or gas place the sensing element as close to the media as possible. These Air Temperature RTD Sensors allow the sensing element to be nearly in direct contact with the air stream. With a housing design containing lots that allow the air to flow past the element, this construction is very popular in measuring air temperature in laboratories, clean rooms, and other locations. When the situation requires a little more protection for the sensor, an option is to use a design similar to the RTD-860. This design has a small diameter probe with a flange for mounting. The configuration will be a little slower to respond to changes in the air stream, but it will provide improved protection for the sensor.

Surface Temperature Measurements

Measuring the temperature of a surface can be one of the most difficult to make accurately. There are a wide variety of styles to choose from, depending on how you want to attach the sensor, how sensitive to changes in temperature the sensor has to be, and whether the installation will be permanent. The most accurate and fastest-responding surface RTD is our SA1-RTD sensor. When applied to a surface, it becomes virtually a part of the surface it is measuring. Surface sensors can also be bolted, screwed, glued, or cemented into place. The RTD-830 has a pre-machined hole in the housing to allow for easy installation with a #4 screw. The RTD-850 has a housing with threaded tip that allows it to be installed into a standard #8-32 threaded hole. This RTD is handy for measuring the temperature of heat sinks or structures where screw holes may already exist.

RTD Glossary

» RTD (Resistance Temperature Detector)

An acronym for resistance temperature detector or device. A resistance temperature detector operates on the principle of the change in electrical resistance in wire as a function of temperature.

» RTD Element

Sensing portion of the RTD which can be made most commonly of platinum, nickel, or copper. OMEGA features two styles of elements: wire wound and thin film.

» RTD Probe

An assembly composed of an element, a sheath, a lead wire, and a termination or connection. The standard OMEGA

RTD probe is made with a 100 ohm platinum European curve element (alpha = 0.00385).

» Platinum RTD

Also known as Pt RTD, Platinum RTD's are typically the most linear, stable, repeatable, and accurate of all RTD's. Platinum wire was chosen by OMEGA because it best meets the needs of precision thermometry.

» Thin Film RTD

Thinfilm RTD's are made up of a thin layer of a base metal embedded into a ceramic substrate and trimmed to produce the desired resistance value. OMEGA RTD's are made by depositing platinum as a film on a substrate and then encapsulating both. This method allows for the production of small, fast response, accurate sensors. Thin film elements conform to the European curve/DIN 43760 standards and the "0.1% DIN" standard tolerance.

» Class A RTD

Highest RTD Element tolerance and accuracy, Class A (IEC-751), Alpha = 0.00385

» Class B RTD

Most Common RTD Element tolerance and accuracy, Class B (IEC-751), Alpha = 0.00385

» Alpha .00385 Curve

European Curve meets "0.1% DIN" standard tolerance and conforms to the DIN 43760 standard

» Sheath

The sheath, a closed end tube, immobilizes the element, protecting it against moisture and the environment to be measured. The sheath also provides protection and stability to the transition lead wires from the fragile element wires. OMEGA’s standard sheaths are 3 mm (1/8") and 6 mm (1/4") O. D. 304 stainless steel tubes. Other O.D.’s and materials are available upon request.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!