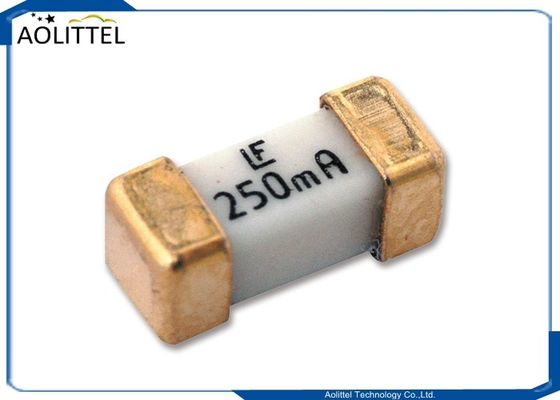

3216FF1.5-R 1206 Fast Blow SMD Chip Encapsulation Surface Mount Fuses 32VAC DC 1.5A With UL CSA RoHS Reach Approved

Benefit

Small size with high current ratings

Excellent temperature stability

High reliability and resilience

Strong arc suppression characteristics

Environmental data

• Thermal Shock: MIL-STD-202, Method 107, Test Condition B (-65 °C to +125 °C)

• Vibration: MIL-STD-202, Method 204, Test Condition C (55 Hz - 2 kHz, 10 G)

• Moisture Resistance: MIL-STD-202, Method 106,10 day cycle

• Solderability: ANSI/J-STD-002, Test B

• Additional resistance to solder heat test: MILSTD-202G Method 210F Condition A

• Operating Temperature: -55 ºC to +125 ºC

• AEC-Q200 qualified (250 mA to 7 A)

______________________________________________________________________________ Download________

Download________

General

Fast-acting fuses help provide overcurrent protection on systems using DC power sources up to 63VDC. The fuse's monolithic,multilayer design provides the highest hold current in the smallest footprint, reduces diffusion-related aging, improves product reliability and resilience, and enhances high temperature

performance. This helps facilitate the development of more reliable, high-performance consumer electronics such as laptops, multimedia devices, cell phones, and other portable electronics.

Features

Multilayer monolithic structure with glass ceramic body and silver fusing element

Silver termination with nickel and pure-tin solder plating,

providing excellent solderability

AEC-Q200 qualified (250 mA to 7 A)

Fast-acting surface mount fuse

Ratings up to 30 amps

Excellent temperature and cycling characteristics

Compatible with reflow and wave solder

RoHS compliant

High temperature performance

-55°C to +125°C operating range

Soldering method

• Wave Immersion: 260 °C, 10 sec max.

• Infrared Reflow: 260 °C, 30 sec max.

Packaging

| Package data |

| Part Number |

Description |

| 12 100 X |

3000 fuses on 8mm tape-and-reel on a 7 inch (178mm) reel per EIA Standard RS481 |

Application

Circuit Protecting in LCD monitors, PC cards, disk drives, portable communication products, PDAs, digital cameras, DVDs, TVs, cell phones, rechargeable battery packs, battery chargers, etc.

Material Specifications

| Construction Body Material |

Ceramic |

| Termination Material |

Silver, Nickel, Tin |

| Fuse Element |

Sliver |

| Terminal Strength |

Hanging test:

0603: 0.5kg 30 seconds;

1206 1.5kg, 30 seconds;

0402 part types meet 2-pound push test

|

Reliability Tests

| No. |

Test |

Requirement |

Test Condition |

Test reference |

| 1 |

Soldering heat resistance |

DCR change ≤±10%

No mechanical damage

|

One dip at (260±5)℃ for (5±1) sec |

MIL-STD-202

Method 210

|

| 2 |

Solderability |

Minimum 95% coverage |

One dip at (235±5)℃ for (5±1) sec |

MIL-STD-202

Method 208

|

| 3 |

Thermal shock |

DCR change ≤±10%

No mechanical damage

|

1000 cycles between -45 ℃ and +125℃ |

Refer to Ao littel Standard |

| 4 |

Moisture resistance |

DCR change ≤±15%

No mechanical damage

|

10 cycles |

MIL-STD-202

Method 106

|

| 5 |

Mechanical vibration |

DCR change ≤±10%

No mechanical damage

|

0.4" D.A. or 30 G between 5- 3000 Hz |

MIL-STD-202

Method 204

|

| 6 |

Mechanical shock |

DCR change ≤±10%

No mechanical damage

|

Fall from 1 m height of the floor 10 times |

MIL-STD-202 Method 213 |

| 7 |

Terminal strength |

DCR change ≤±10%

No mechanical damage

|

30 sec. hanging for 1206 (1.0kg) and 0603 (0.5KG) |

Refer to Ao littel Standard |

| 8 |

Life |

No electrical "opens" during testing voltage drop change shall be less than±20% of initial value |

80% Rated current ambient temperature +25℃ to +28 ℃,2000 hours |

Refer to Aolittel Standard |

| 9 |

Bending |

No electrical "opens" during testing |

2 mm bending ,more than 5 seconds |

Refer to Ao littel Standard |

Cautions and warnings:

1,Handling CHIP FUSE must not be dropped. Chip-offs must not be caused during handling of FUSEs. Components must not be touched with bare hands. Gloves are recommended. Avoid contamination of fuse surface during handling.

2,Soldering Use resin-type flux or non-activated flux. Insufficient preheating may cause ceramic cracks. Rapid cooling by dipping in solvent is not recommended. Complete removal of flux is recommended.

3,Mounting Electrode must not be scratched before/during/after the mounting process. Contacts and housings used for assembly with fuses have to be clean before mounting. During operation, the fuse’s surface temperature can be very high (ICL). Ensure that adjacent components are placed at a sufficient distance from the fuse to allow for proper cooling of the fuses. Ensure that adjacent materials are designed for operation at temperatures comparable to the surface temperature of the fuse. Be sure that surrounding parts and materials can withstand this temperature. Avoid contamination of fuse surface during processing.

4,Operation Use fuses only within the specified operating temperature range. Environmental conditions must not harm the fuses. Use fuses only in normal atmospheric conditions. Contact of chip fuses with any liquids and solvents should be prevented. It must be ensured that no water enters the chip fuse (e.g. through plug terminals). For measurement purposes (checking the specified resistance vs. temperature), the component must not be immersed in water but in suitable liquids (e.g. Galden). Avoid dewing and condensation.

Notice: Specifications of the products displayed herein are subject to change without notice. We assume no responsibility or liability for any errors or inaccuracies. Information contained herein is intended to provide a product description only. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document. Except as provided in Aolittel's terms and conditions of sale for such products, Aolittel assumes no liability whatsoever, and disclaims any express or implied warranty, relating to sale and/or use of Wayon products including liability or warranties relating to fitness for a particular purpose, merchantability, or infringement of any patent, copyright, or other intellectual property right. Specifications are subject to change without notice.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!