MZ31 MZ32 PTC Thermistor SY 16P 5 OHM 120C 900mA For Inverter Welding Machine

I Description Of The MZ31 MZ32 PTC Thermistor SY 16P

MZ21 Type Thermistor used for overcurrent protection in telecommunication and AC circuit.

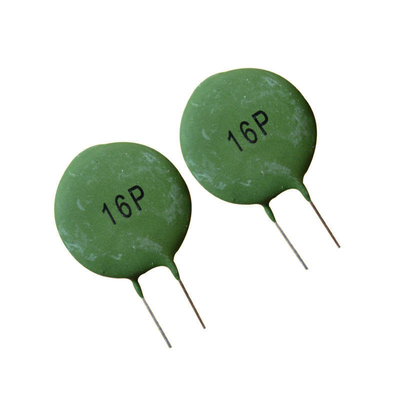

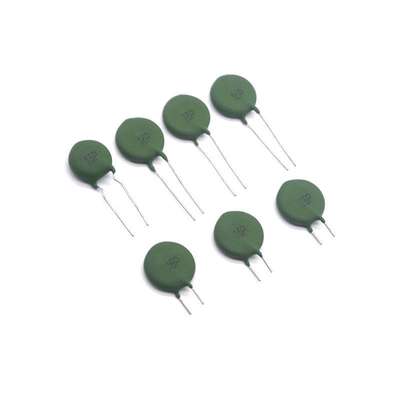

Model Number:MZ31 series 15P,16P,19P type

Function:PTC Thermistor Special for over current,overload protection of welding machines.

Technical parameters of Welding machine overload protection PTC Thermistor:

16P nominal R25 resistance: conventional 6 Ω, also 3.7 Ω, 5 Ω, 7 Ω, 10 Ω, 12 Ω, 15 Ω

15P, 19P nominal resistance: Conventional 15P 101R-100Ω, 19P 101R-100Ω,also 39 Ω, 50 Ω, 120 Ω

Allow R25 resistance deviation: 100 Ω ± 30%, others: ± 25 %

Rated power: 0.5 W

The above three models are all used for overcurrent overload protection of welding machines, just different welding machine size use different PTC thermistor Model.

II Brief Introduction Of The MZ31 MZ32 PTC Thermistor SY 16P

MZ31 series 15P,16P,19P PTC thermistor are million- time safety thermistor of automatic circuit protection,recoverability, using repeatedly, and no trigger, noise or protective component that could protect and restore from abnormal temperature and current automatically,which called "auto restore fuse" and "ten-thousand-time fuse".Recoverability, using repeatedly, and no trigger, noise or sparks.

III Working Principle Of The MZ31 MZ32 PTC Thermistor SY 16P

When the circuit is in normal state, the current passing through the PTC thermistor is less than the rated current, and the PTC thermistor is normal and the resistance is small.Does not affect the normal operation of the protected circuit. When the circuit fails and the current greatly exceeds the rated current, the PTC thermistor suddenly heats up and is in a high resistance state. The circuit is disconnected to protect the circuit from damage. When the failure is eliminated, the PTC thermistor automatically returns to a low resistance state and the circuit returns to normal operation.

IV Overall Dimension Of The MZ31 MZ32 PTC Thermistor SY 16P

| Part No |

DMAX |

W±1.0 |

TMAX |

Φd±0.05 |

| MZ21- P500RMN |

18.0 |

5.0 |

5.0 |

0.8 |

V Characteristics Curve Of The MZ31 MZ32 PTC Thermistor SY 16P

VI Electrical Performance Of The MZ31 MZ32 PTC Thermistor SY 16P

| part no |

rated

resistance

(25℃±1℃)

|

switch

temperature

(±7℃)

|

break down

voltage

Ac

|

non-operating current

(at 40℃)

|

typical trip current |

Operating ambient temperature range |

| MZ21- P500RMN |

5Ω±20% |

120℃ |

300 V |

450 mA |

900 mA |

-10~+45℃ |

VII Advantage Of The MZ31 MZ32 PTC Thermistor SY 16P

1.Automatic circuit protection,can resume steadily,

2.contactless,noiseless and flameless,

3.reacts fast,

4. with a better performance of overvoltage protection,

5.wide operating voltage range,

6.small steady resistance,

7.low rated current,

8.small resistance,small size,

9.stable for a long time,

10.no need to be reset supply after overload protection,

11.wide operating temperature range, 0 ~ +60°C (V=Vmax), -25 ~ +125°C (V=0),

12.RoHS compliant.

Special PTC Thermistor for Welding machine overload protection

Appearance and Dimension(In: mm)

15P Thermistor:

finished product diameter 15.5-16 .0 mm, mold size is 16mm.

Foot distance is 7.5 ± 0.5 mm.

Foot length: the length of the cut foot is 5mm.

16P Thermistor: finished product diameter 17-17 .5 mm, mold size is 20 mm.

Foot distance is 5 ± 0.5 mm.

Foot length: the length of the cut foot is 8mm.

19P Thermistor:

finished product diameter 17.5-18 .0 mm, mold size is 20mm.

Foot distance is 7.5 ± 0.5 mm.

Foot length: the length of the cut foot is 6mm.

16P is thinner than 15P and 19P is thicker than 15P and 16P.

VIII Application Of The MZ31 MZ32 PTC Thermistor SY 16P

Inverter welding machine is more and more popular in the world since technoloy required for manufacturing,however, good protection can assured inverter welding machine functioning well for long term. We can supply all set of components for overcurrent protection / overvoltage protection. Below is lists we supplying our customers for your ref:

| Varistor |

07D361K

10D471K 10D681K

14D330K 14D151K 14D221K 14D391K

20D820K 20D102K 20D121K 20D121K 20D391K 20D471K

25D431K 25D751K 25D681K 25D821K

32D431K 25D751K 32D681K 32D821K |

| PTC Thermistor |

126A 15P 16P 16P5R0M265 08M12RM265 05M120-180 19P MZ72-18ROM MZ11-13N13-20 MZ12-16P2R1H140,MZ12-16P4R7H140,MZ11-16P5R0H265,MZ11-16P6R0H265,MZ11-16P7R0H265,MZ11-16P10RH265,MZ11-16P12RH265,MZ72-18RM |

| NTC Thermistor |

2.5D-20 5D-20 8D-20 47D-15 2.5D-15 47D-20 |

| Fuse |

Glass fuse/Ceramic fuse 3.6x10mm/5x20mm/6.35x31.8mm/10x38mm STP/SFP/BTC/BFC/BMT/BMF/PTU/PFU

Micro Fuse MTS/MFS/NTS/NFS/TMS/FMS 8x4x8mm

Surface Mount Fuse 6125 2410 SET/SEF/SFE/STE/SST/SSF |

VIIII Manufacturing Process Of The MZ31 MZ32 PTC Thermistor SY 16P

Weighing ⇒ Ball Milling ⇒ Presintering ⇒ Granulation ⇒ Forming ⇒ Sintering ⇒ Add electrode ⇒ Resistance

sorting ⇒ Pressure line ⇒ Package insulation ⇒ Assembly ⇒ Withstand voltage detection ⇒ Resistance

Inspection ⇒ Final inspection ⇒ Packaging ⇒ Put into warehouse .

X Other part number Of The MZ31 MZ32 PTC Thermistor SY 16P

MZ11-10N12RH250,MZ11-10N18RH265,MZ11-10N22RH265,MZ11-10P15RH265,MZ11-10P39RH265

SPMZB-9H25RH265,SPMZB-9Z1R0H15,SPMZB-9Z1R2H15,SPMZB-9Z1R8H15

WMZ12A-10RM180,WMZ12A-10RM220,WMZ12A-12RM090,WMZ12A-12RM170,WMZ12A-15RM070,

WMZ12A-15RM130,WMZ12A-15RM145,WMZ12A-15RM160,WMZ12A-15RM200,WMZ12A-18RM150,

WMZ12A-20RM070,MZ212A-20RM085,MZ23-20RM100,MZ25-20RM145,WMZ12A-22RM100,

WMZ12A-22RM120,WMZ12A-22RM130,WMZ12A-22RM180,MZ25-25RM055,MZ25-25RM060,

WMZ12A-25RM065,MZ25-25RM085,MZ25-25RM100,MZ25-25RM120,WMZ12A-33RM110,WMZ12A-35RM060,

MZ23-35RM090,WMZ12A-39RM085,WMZ12A-39RM100,MZ23-40RM080,WMZ12A-47RM055,WMZ12A-47RM090,

WMZ12A-50RM060,MZ23-50RM070,MZ23-50RM075,WMZ12A-55RM060-MZ23-55RM070,WMZ12A-62RM050,

WMZ12A-62RM075,WMZ12A-68RM045,WMZ12A-68RM050,WMZ12A-68RM055,WMZ12A-68RM060,

WMZ12A-75RM045,WMZ12A-82RM040,WMZ12A-68RM060,WMZ12A-101M030,WMZ12A-101M035,

WMZ12A-101M040,WMZ12A-101M045,WMZ12A-101M050,WMZ12A-101M055,WMZ12A-121M030,

WMZ12A-121M035,WMZ12A-121M050,WMZ12A-151M025,WMZ12A-151M030,WMZ12A-151M035,

WMZ12A-151M040,WMZ12A-221M020,WMZ12A-221M025,WMZ12A-471M006,WMZ12A-681M005,

WMZ12A-102M004,WMZ12A-152M003,WMZ12A-222M002

Hot Tags: MZ31 16P Positive Temperature Coefficient Thermistor 18MM PTC Thermistor Resistance, China, Manufacturers, Suppliers, Factory, Made in China, Wholesale, Buy, Customized, in stock, Bulk, Free Sample, Cheap, Discount, Buy discount, Low price, Price, Price list, Quotation

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!