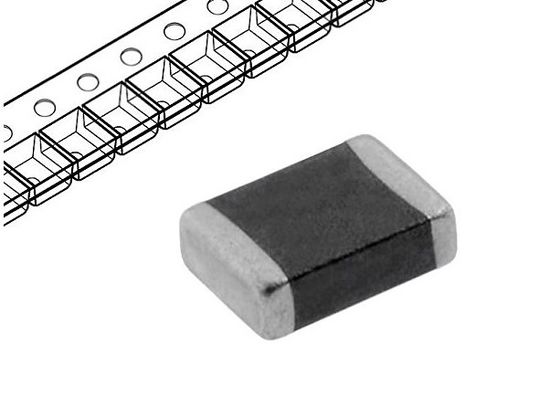

Low Voltage SMD 1812 Multilayer Chip Metal Oxide Varistors MVR1812-390H 39V 800A 2500pF 3.1J 4532 Metric Surface Mount

Description

The MVR Series of low voltage varistors is designed to protect sensitive electronics devices against high voltage surges in the low voltage region. They offer excellent transient energy absorption due to improved energy volume distribution and power dissipation. Low voltage varistors cover wide DC operating voltage range from 3V to 170V. The MVR Series is the same except for higher operating temperatures up to 150ºC. MVR varistors are typically applied to protect components at the circuit board level.

Features

* Sizes available: 0603, 0805, 1206, 1210, 1812, and 2220

* Nickel barrier terminations

* AC operating voltage range from 2 VRMS to 130 VRMS

* DC operating voltage range from 3 VDC to 170 VDC

* No plastic coating for a better flammability rating

* Inherently bi-directional

* Operating temperature range from -55°C to +125°C

* Compliant with AEC-Q200 (Grade 1)

Application

• On-board protection of voltage sensitive IC’s and transistors

• Fire and carbon monoxide detection

• Sensors and monitoring equipment

• Timers

• Auto and heavy equipment instrumentation

• ESD protection for components sensitive to IEC 1000-4-2, MIL-STD 883C Method 3015.7 and other industry specifications

• Suppression of inductive switching or other low to medium transient events at the circuit board level • Provides on-board transient voltage protection of ICs and transistors

• Replace larger surface mount TVS Zeners in many applications

• Used to help achieve electromagnetic compliance of end products

• 6 model sizes available 0603, 0805, 1206, 1210, 1812 and 2220

Size(mm)

| Type |

Length(L) |

Width(W) |

High(H) |

Termination(L1) |

| 1812 |

4.50±0.40 |

3.20±0.30 |

2.50(max) |

0.75±0.25 |

Electrical Parameters

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8/20uS(A) Ip(MAX)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MVR1812-3R0G

|

1.4

|

2

|

3

|

2.4~3.6

|

9

|

20

|

|

|

|

|

|

|

|

MVR1812-5R0G

|

2.4

|

3.3

|

5

|

4.0~6.0

|

12

|

20

|

60

|

80

|

|

|

|

|

|

MVR1812-8R0G

|

4

|

5.5

|

8

|

7.0~10.5

|

14

|

20

|

60

|

80

|

250

|

400

|

|

|

|

MVR1812-120G

|

7

|

9

|

12

|

10~14

|

24

|

20

|

60

|

80

|

250

|

400

|

800

|

|

|

MVR1812-180G

|

11

|

14

|

18

|

15.5~21

|

30

|

20

|

80

|

100

|

250

|

400

|

800

|

500

|

|

MVR1812-240G

|

14

|

18

|

24

|

22-27

|

38

|

20

|

80

|

100

|

250

|

500

|

1200

|

500

|

|

MVR1812-270G

|

17

|

22

|

27

|

24~30

|

42

|

20

|

80

|

100

|

250

|

500

|

1200

|

500

|

|

MVR1812-330G

|

20

|

26

|

33

|

29~36

|

54

|

20

|

80

|

100

|

250

|

500

|

1200

|

500

|

|

MVR1812-390G

|

24

|

30

|

39

|

35~42

|

65

|

20

|

80

|

100

|

250

|

500

|

1200

|

500

|

|

MVR1812-470G

|

28

|

36

|

47

|

42~52

|

77

|

20

|

80

|

100

|

250

|

500

|

1200

|

500

|

|

MVR1812-560G

|

35

|

45

|

56

|

50~62

|

90

|

|

80

|

100

|

250

|

500

|

1200

|

500

|

|

MVR1812-680G

|

40

|

56

|

68

|

60~75

|

110

|

|

|

100

|

250

|

500

|

1200

|

500

|

|

MVR1812-820G

|

50

|

65

|

82

|

73~91

|

135

|

|

|

80

|

200

|

300

|

800

|

500

|

|

MVR1812-101G

|

60

|

85

|

100

|

90~110

|

165

|

|

|

80

|

200

|

300

|

800

|

500

|

|

MVR1812-121G

|

75

|

100

|

120

|

108~132

|

200

|

|

|

|

200

|

300

|

500

|

500

|

|

MVR1812-151G

|

95

|

125

|

150

|

135~165

|

250

|

|

|

|

|

300

|

500

|

500

|

|

MVR1812-181G

|

115

|

150

|

180

|

162~198

|

300

|

|

|

|

|

|

500

|

500

|

|

MVR1812-201G

|

130

|

170

|

205

|

184~226

|

340

|

|

|

|

|

|

|

500

|

|

MVR1812-221G

|

140

|

180

|

220

|

198~242

|

360

|

|

|

|

|

|

|

500

|

|

MVR1812-241G

|

150

|

200

|

240

|

216~264

|

395

|

|

|

|

|

|

|

500

|

|

MVR1812-271G

|

175

|

225

|

270

|

243~297

|

455

|

|

|

|

|

|

|

500

|

|

MVR1812-361G

|

230

|

300

|

360

|

324~396

|

595

|

|

|

|

|

|

|

500

|

|

MVR1812-391G

|

250

|

320

|

390

|

351~429

|

650

|

|

|

|

|

|

|

500

|

|

MVR1812-431G

|

275

|

350

|

430

|

387~473

|

710

|

|

|

|

|

|

|

400

|

|

MVR1812-471G

|

300

|

385

|

470

|

423~517

|

775

|

|

|

|

|

|

|

400

|

Enviromental Reliability Test

| Characteristic |

Test method and description |

| High Temperature Storage |

The specimen shall be subjected to 125℃ for 1000 hours in a thermostatic bath without load and then stored at room temperature and humidity for 1 to 2 hours. The change of varistor voltage shall be within 10%. |

| Temperature Cycle |

The temperature cycle of specified temperature shall be repeated five times and then stored at room temperature and humidity for one two hours. The change of varistor voltage shall be within 10%and mechanical damage shall be examined. |

Step |

Temperature |

Period |

| 1 |

-40±3℃ |

30min±3 |

| 2 |

Room Temperature |

1~2hours |

| 3 |

125±2℃ |

30min±3 |

| 4 |

Room Temperature |

1~2hours |

| High Temperature Load |

After being continuously applied the maximum allowable voltage at 85℃ for 1000hours, the specimen shall be stored at room temperature and humidity for one or hours, the change of varistor voltage shall be within 10%. |

|

Damp Heat Load/

Humidity Load

|

The specimen should be subjected to 40℃,90 to 95%RH environment, and the maximum allowable voltage applied for 1000 hours, then stored at room temperature and humidity for one or two hours. The change of varistor voltage shall be within 10%. |

| Low Temperature Storage |

The specimen should be subjected to -40℃, without load for 1000 hours and then stored at room temperature for one two hours. The change of varistor voltage shall be within 10%. |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!